4.0 audit

Activating the right digital ways to improve your industrial performance

Start your audit 4.0

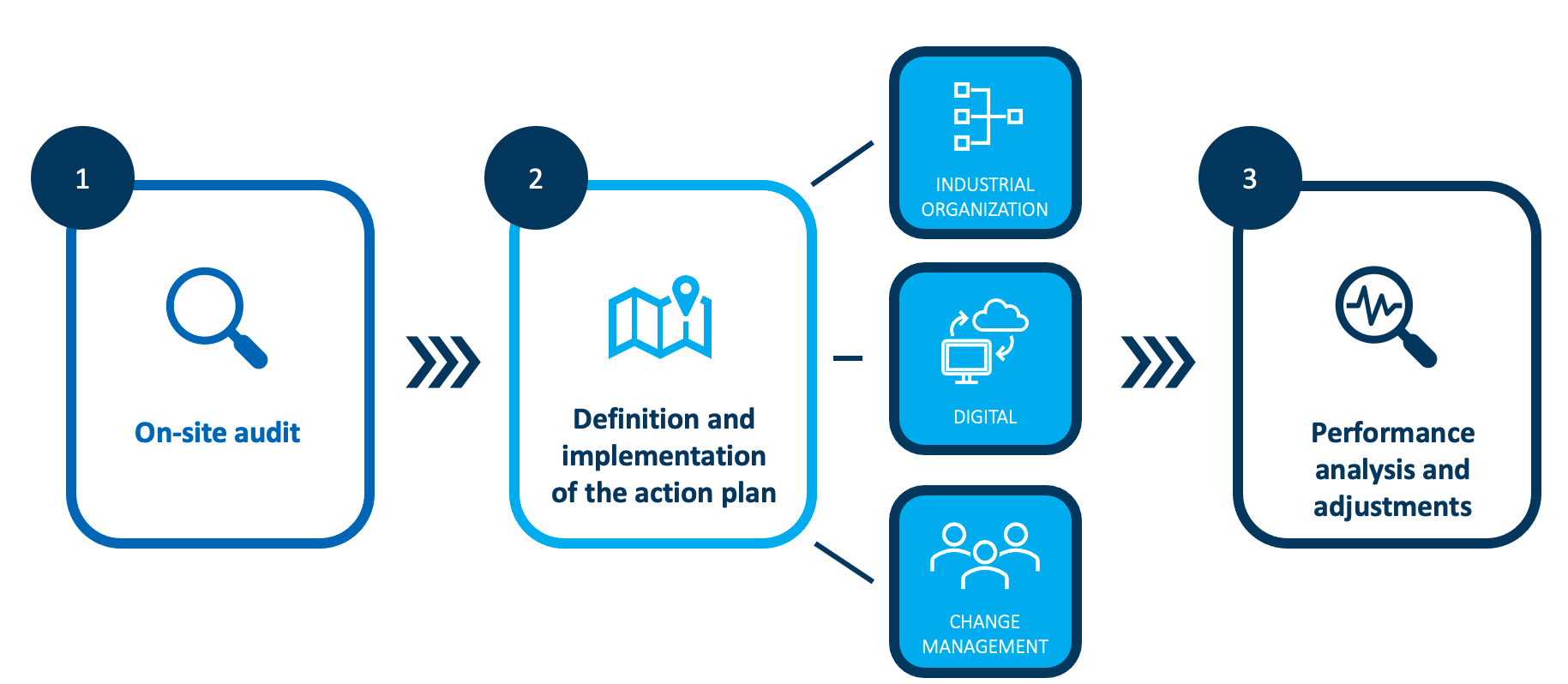

The 4.0 audit proposed by Inoprod aims to measure the digital maturity of your organization and to develop an action plan based on your strategic and operational issues. The first step of the audit consist in giving you a diagnosis which includes:

- An inventory of your industrial digital ecosystem

- An analysis and evaluation of your different processes (production, maintenance, logistics, etc.)

- A structural and technological action plan staggered according to your operational and strategic priorities

The 3 pillars of your action plan

Depending on the results of the diagnosis 4.0, our experts will support you on all or part of the following pillars:

KPI TP measure the effectiveness of the action plan

Different performance indicators will be built to analyze and measure the success of your action plan.

Below, is an example of KPI’s according to the pillars:

- Industrial organization : the creation of dashboards, the creation of a digital twin to anticipate and optimize production control.

- Integration of digital softwares : utilization rate, benchmarking before/after implementation of the solution.

- Support for change : Field survey, skills assessment, etc.

They trust us

Mecatherm

More flexible and efficient production lines with Tecnomatix® Plant Simulation.

Learn more

Comau

Securing the production and performance of a production line by a dynamic simulation

Learn more