Conception and integration of industrial equipment

Example of projects performed by our experts

Pre-sizing, sizing, and validation of equipment

Inoprod is frequently solicited to carry out pre-sizing, sizing and validation of equipment integrated into special machines. From the simple verification of structural strength to the complex modeling of a mechanical system integrating the kinematics of the equipment and non-linearity of the contacts, Inoprod can check the compliance with the normative requirements (Eurocodes, CM66, EN13 0001, EN 13 155, etc.) or expected performance requirements.

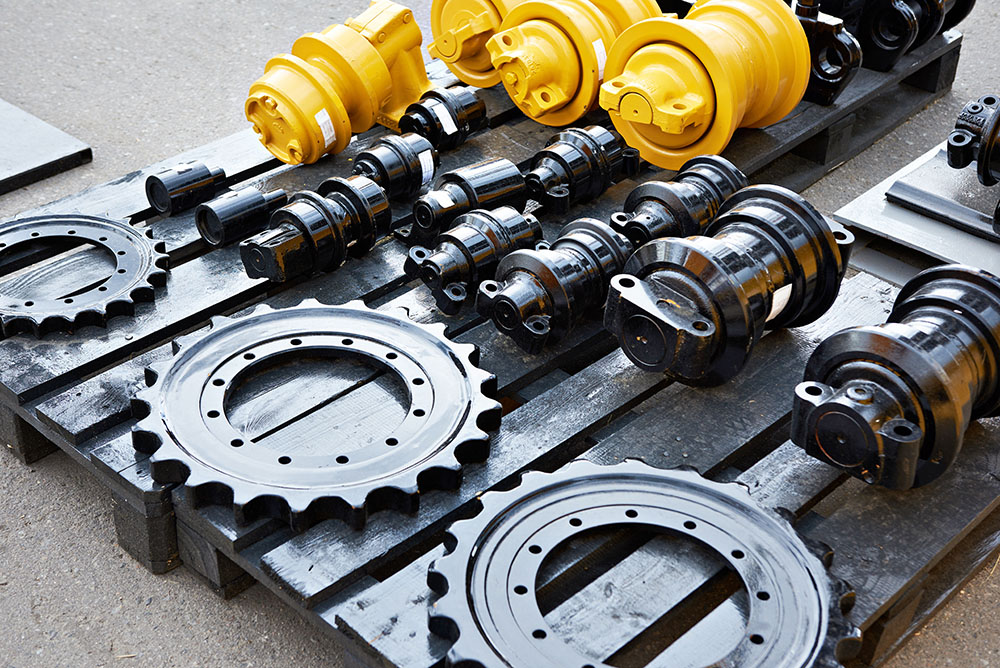

Securing the manufacturing and performance of a production line

COMAU is specialized in the design of automated production lines for the automotive industry. COMAU is responsible for developing an engine block production line. Regarding the complexity of the flows and the simultaneity of the line parameters, COMAU called on Inoprod’s know-how to:

- Validate the design and achievement of the capacity objectives of the future production line.

- Secure purchases.

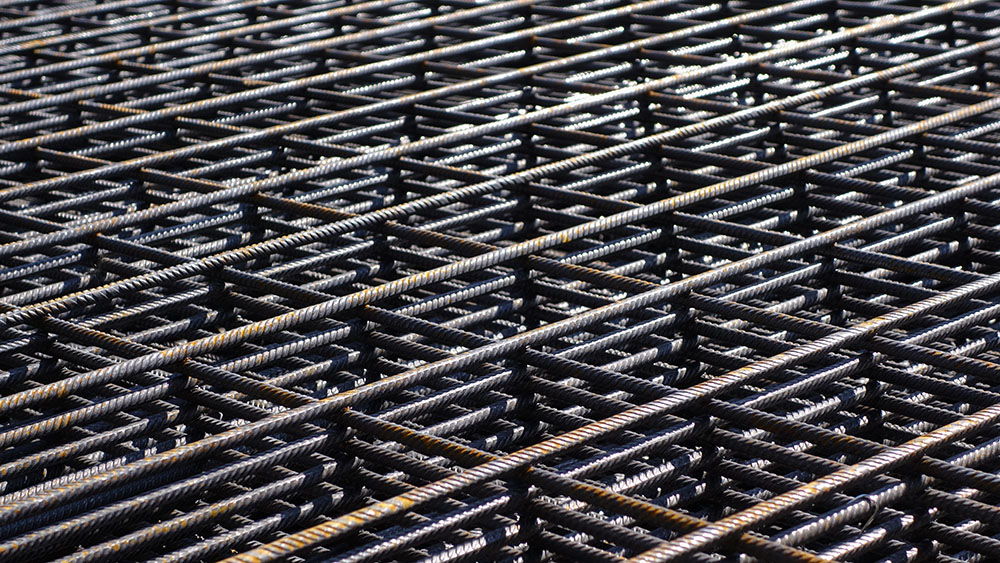

Development of a welded mesh manufacturing line

As part of the development of the automated welded mesh manufacturing line, our client wished to rely on the experience of our team of experts in 3D dynamic flow simulation, to secure each of the following project phases:

- Feasibility: Definition of the necessary resources and process times to reach the capacity defined in the specifications.

- Développement : Étude détaillée via un modèle de flux 3D dynamique. Cette étude a consisté à représenter en 3D l’ensemble de la machine développée par le bureau d’études client et valider les temps process des solutions techniques retenues. Cette étude a permis de mettre en évidence les risques process et d’identifier les points techniques devant être optimisés afin de répondre aux besoins client.

- Development: Detailed study via a dynamic 3D flow model. This mission consisted in representing the entire machine in 3D developed by the client design department and validating the process times of the technical solutions adopted. The process risks could be highlighted, and the technical points could be identified, and both were optimized in order to meet customer needs.

- Validation: This last design phase consisted of readjusting the parameters of the flow simulation model previously developed to definitively validate the design choices before going into production.